Retail Supply Chain Management: Definition & Strategies

Team Locus

In this article

Key Takeaways

- Retail supply chain management is evolving rapidly as consumer expectations rise, margins shrink, and omnichannel operations grow more complex, making it a true differentiator in 2025.

- The supply chain covers procurement, inventory, warehousing, logistics, and returns, and every stage plays a direct role in shaping customer satisfaction.

- Strong supply chain processes help retailers avoid stockouts, protect margins, ensure fast deliveries, and stay flexible across multiple channels.

- Retailers continue to face challenges, including post-pandemic disruptions, labor shortages, climate risks, and technology gaps, which demand smarter and more agile systems.

- Locus enables retailers to simplify this complexity with AI-powered optimization, real-time visibility, and automated decision-making, which reduces costs and improves reliability.

If your meetings are often about “How do we keep up with rising consumer expectations without crushing margins?” or “How do we deliver consistently across multiple channels without driving up costs of stockouts?”, you are probably facing challenges with your retail supply chain management.

After all, your retail supply chain hinges on every step, from sourcing raw materials to last-mile delivery. Get it wrong, and the result is higher costs, empty shelves, and lost loyalty. Get it right, and you unlock efficiency, resilience, and long-term growth.

This blog defines retail supply chain management, outlines its key components, and examines the challenges retailers must address. We’ll also explore proven strategies, essential KPIs, and how AI-powered solutions like Locus simplify operations, improve routing efficiency, and build supply chains ready for the future.

What is the Retail Supply Chain?

In retail, the supply chain covers everything from sourcing products to delivering them to the final customer. It covers every stage, including procurement, manufacturing, warehousing, distribution, and fulfillment, before goods reach store shelves or are delivered to a shopper’s doorstep. Compared to traditional supply chains, retail supply chains must strike a balance between speed, cost, and flexibility while adapting to fluctuating consumer demand.

A typical retail supply chain begins with sourcing raw materials or finished goods from suppliers. These products are then transported to warehouses or distribution centers, where they are stored, picked, and packed for delivery. From there, they move through transportation networks to reach physical stores or directly to consumers in the case of e-commerce.

Omnichannel retail has further expanded this model, requiring retailers to integrate physical and digital channels seamlessly. Customers expect to order online and pick up in-store, return products through multiple channels, or receive same-day delivery. This makes visibility, data-driven planning, and responsive logistics essential.

What is Retail Supply Chain Management?

Retail supply chain management involves planning and controlling procurement, inventory, warehousing, transportation, and fulfillment activities. It provides a framework for decision-making that enables retailers to align suppliers, distribution centers, and sales channels around meeting consumer demand. When analyzing how supply chain management works in retail, it becomes clear that visibility and agility are critical.

For example, if a customer orders a product online and requests in-store pickup, the retailer must synchronize stock availability across multiple nodes and execute fulfillment without delays. This seamless coordination is only possible when the supply chain is designed with integrated systems and advanced analytics.

In practice, retail supply chain management is both an operational necessity and a strategic differentiator. Companies that invest in digital tools and intelligent orchestration gain the ability to lower costs, shorten delivery cycles, and increase customer loyalty in highly competitive markets.

Why is Supply Chain Management Important in Retailing?

To understand why supply chain management is important in retailing, consider the role it plays in shaping every customer interaction. When products are available on shelves or online when shoppers need them, it’s because the supply chain is working smoothly in the background.

Moreover, when an order arrives on time and without errors, that’s supply chain management creating trust and reliability.

That said, below are some of the reasons why supply chain management is essential in retailing:

- Avoids stockouts and excess inventory: Retailers with efficient supply chains ensure that products are always available when customers need them, while avoiding unnecessary overstock that drains resources. This balance protects both customer satisfaction and financial health.

- Protects profit margins: An optimized supply chain lowers transportation, warehousing, and handling costs without compromising service quality. By keeping expenses under control, retailers maintain more substantial margins in highly competitive markets.

- Delivers consistent service quality: Customers value reliability, and a strong supply chain ensures orders are processed, shipped, and delivered smoothly every time. This consistency builds trust and encourages repeat purchases.

- Enables faster delivery: Speed has become a defining factor in retail success, and supply chain efficiency enables rapid fulfillment. Retailers that meet delivery promises gain a competitive edge and improve customer satisfaction.

- Supports flexible returns: Modern customers expect easy returns, and supply chain management makes this process seamless across both physical and digital channels. A hassle-free return policy encourages more confident purchasing.

- Builds resilience against disruptions: Unforeseen events, such as supplier delays or market shifts, can easily disrupt operations, but a well-structured supply chain adapts quickly. The agility reduces risks and keeps businesses running smoothly.

- Strengthening customer loyalty: When customers receive their orders on time and enjoy a smooth shopping journey, they are far more likely to return. Over time, efficient supply chains turn satisfaction into lasting loyalty.

📌 Download our whitepaper: Smarter Logistics with Locus Routing Constraints

Core Components of the Retail Supply Chain

Retail supply chains are built from interconnected stages that determine how efficiently products move from suppliers to shoppers. Each stage carries its own challenges, but also opportunities for improvement when handled strategically.

Procurement and Sourcing

Retailers make critical decisions here, such as choosing between global and local suppliers.

A fashion brand, for instance, may source fabric from overseas for cost savings, but partner with local factories for faster response to seasonal trends. The trade-off between cost and agility begins at the procurement stage.

Inventory Management

Inventory is where many retailers struggle. Grocery chains, for example, need to manage perishable goods with short shelf lives.

When you stock too little, the shelves stay empty. On the other hand, when you stock too much, waste becomes costly. Accurate demand forecasting, supported by digital route optimization tools, enables retailers to keep products moving without tying up excess capital.

Warehousing and Fulfillment

Warehouses are no longer just storage hubs. Locus pioneered the model of fulfillment centers that rapidly pick, pack, and ship orders.

Now, even mid-sized retailers use micro-fulfillment centers near urban areas to speed up last-mile delivery. These facilities reduce the gap between customer demand and product availability.

Transportation and Logistics

Transportation connects every link of the chain. A furniture retailer, for example, may rely on trucking fleets for regional deliveries, while using third-party couriers for last-mile service.

Tools like logistics route planning and automated route planning help cut empty miles, lower fuel costs, and improve delivery reliability.

Returns and Reverse Logistics

Reverse logistics has become a defining factor in customer loyalty. For example, brands can build their reputation on hassle-free returns, showing how effective return policies can turn potential losses into repeat sales.

Handling returns efficiently also reduces costs and supports sustainability goals through recycling or resale programs.

📌 Related reading: How to Prevent Retail Supply Chain Attacks

Retail Supply Chain Management Challenges

Even the strongest retail supply chain can encounter roadblocks. The challenges in retail supply chain management span external shocks, operational inefficiencies, and technology risks.

Here are some of the most common ones:

Post-COVID Disruptions

Global supply chains remain vulnerable to pandemic-era legacies like shipping delays and supplier shutdowns. For example, many US retailers still face container shortages when sourcing from Asia, creating unpredictable lead times.

How Locus helps: Locus Control Tower provides complete visibility into shipments, highlighting risks early, allowing retailers to reroute orders and communicate accurate delivery timelines to customers.

Labor Shortages

Warehouses and trucking fleets struggle to find skilled staff, especially during peak seasons. A toy retailer preparing for the holiday rush, for instance, may face late shipments when order volumes outpace available workers.

How Locus helps: By automating dispatch and optimizing fleet capacity, Locus reduces dependence on large labor pools, keeping operations stable during seasonal or unexpected spikes.

Geopolitical Risks and Climate Events

Trade restrictions, fuel price hikes, and extreme weather can halt production or raise logistics costs. Textile retailers sourcing from flood-prone regions in Southeast Asia often see significant delays during the monsoon season.

How Locus helps: Locus uses a route planning system to identify alternate suppliers and transportation modes, reducing reliance on single regions or vulnerable trade routes.

Cybersecurity Threats

Retailers are prime targets for ransomware and data breaches, which can stall fulfillment and damage customer trust. For example, a cyberattack on a large North American retailer in 2023 resulted in distribution networks being idle for several days.

How Locus helps: Locus integrates securely with OMS, WMS, and ERP systems, providing enterprise-grade protection while centralizing logistics data on a single platform.

Technology Adoption Gaps

AI, IoT, and advanced analytics promise efficiency but require thoughtful execution. Retailers that deploy disconnected tools often end up with fragmented data that cannot inform decisions.

How Locus helps: Locus provides an AI-powered orchestration platform that unifies data across procurement, warehousing, and delivery, enabling faster and more accurate supply chain decisions.

📌 Download our whitepaper: Clean Data, Lean Logistics

5 Strategies to Improve Retail Supply Chain Management

Knowing how to improve retail supply chain management starts with addressing weak spots while building resilience for the future. The following strategies combine proven practices with advanced technology to meet both operational needs and customer expectations.

Demand Forecasting and Planning

Poor forecasting often leads to stockouts or overstock situations, both of which damage profitability. A grocery retailer that underestimates demand for seasonal items risks empty shelves, while one that overestimates ties up cash in unsold stock. This highlights how supply chain management works in retail by directly linking forecasting accuracy to business outcomes.

How Locus helps: Locus AI-powered delivery software analyzes historical sales, customer demand patterns, and market signals to generate precise forecasts. This enables retailers to maintain optimal stock levels while enhancing service reliability.

Building Resilient Supplier Networks

Global retailers relying on a single overseas supplier remain exposed to risks such as trade restrictions or natural disasters. For example, fashion brands that source fabric from a single country often face delays during climate events or geopolitical tensions. These cases highlight the challenges in retail supply chain management when supplier diversity is missing.

How Locus helps: Locus provides supplier visibility and analytics that help retailers assess lead times, costs, and risks. With this intelligence, businesses can diversify supplier bases and switch seamlessly when disruptions occur.

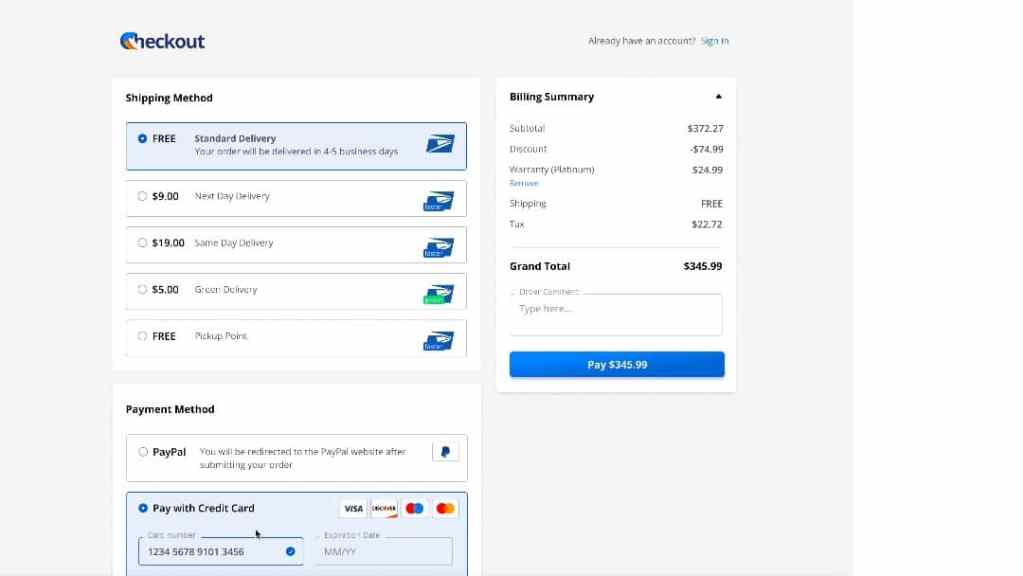

Omnichannel Fulfillment Optimization

Consumers now expect the flexibility to buy online, pick up in-store, or request home delivery. A pharmacy chain that cannot synchronize online inventory with store availability risks disappointing customers and losing sales.

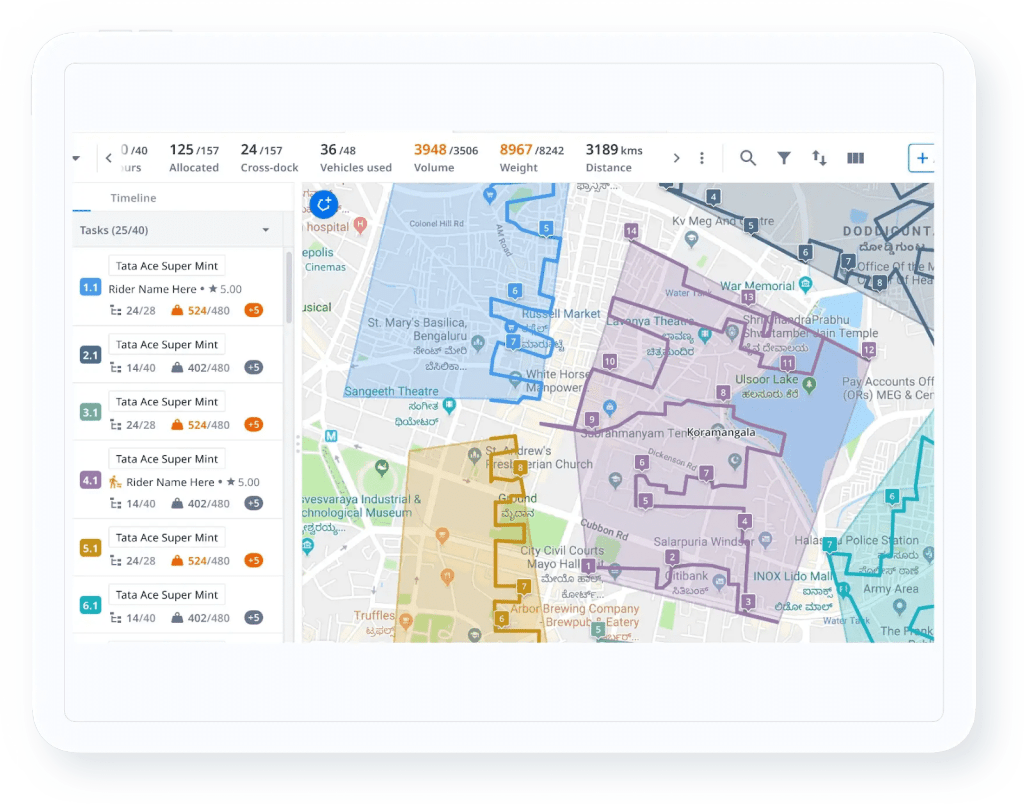

How Locus helps: Locus optimizes route management and integrates multiple fulfillment nodes, including warehouses, stores, and dark stores, enabling retailers to meet demand consistently across all channels.

Automation and Digital Transformation

Manual dispatching and siloed workflows lead to increased delivery costs and slower response times. A furniture retailer assigning static delivery routes without digital tools often suffers from wasted capacity and missed delivery slots. To achieve the benefits of supply chain management for retailers, automation is now a crucial component.

How Locus helps: With automated route planning and dispatch management process tools, Locus streamlines fleet utilization, reduces delivery times, and scales operations without additional workforce pressure.

Sustainability Initiatives

Customers and regulators are increasingly pressuring retailers to reduce carbon emissions. A fashion retailer offering free returns may see rising waste if returned goods are sent to landfills rather than recycled or resold. Addressing this challenge is crucial to improving retail supply chain management in a way that supports long-term growth.

How Locus helps: Locus uses TDMS real-timedispatch management and advanced optimization to minimize empty miles, reduce fuel consumption, and create eco-friendly logistics operations without compromising efficiency.

📌 Related read: What Is Route Scheduling?

KPI Tracking and Metrics

Retail supply chain performance cannot be left to guesswork. Success depends on measuring the right indicators and using those insights to guide continuous improvement.

In the retail and CPG industry, these KPIs highlight both customer-facing results and operational efficiency.

- On-time delivery rate: Deliveries that arrive late erode trust and increase support costs. A furniture retailer that promises same-day delivery but consistently misses the window will struggle to retain repeat customers. Monitoring this KPI shows how well delivery commitments are met. Strong route efficiency has a direct influence on this outcome.

- Inventory turnover: High turnover indicates that products are selling at the right pace, while slow-moving stock ties up capital. Grocery retailers track this closely to prevent waste from perishable goods.

- Order accuracy: Mistakes in order fulfillment create frustration and costly returns. If an electronics retailer ships the wrong model or accessory, the error disrupts the customer relationship and reduces margins. Accuracy remains one of the most visible signs of operational discipline.

- Fulfillment cycle time: This metric measures the time it takes for an order to move from confirmation to delivery. In competitive categories such as cosmetics or fashion, short cycle times are crucial for meeting rising consumer expectations. Techniques like strategic route planning help reduce delays by optimizing movement across nodes.

- Customer satisfaction: These metrics, such as NPS and CSAT, demonstrate how supply chain performance translates into loyalty. Flexible returns, transparent updates, and reliable delivery experiences often matter as much as product quality itself. Strong alignment with a modern carrier management platform supports consistent experiences across multiple delivery partners.

📌 Also read: Why Change Management Matters in Retail Logistics

How Locus Simplifies Retail Supply Chain Management in 2025?

Enterprises in the retail and CPG industry need platforms that bring speed, accuracy, and visibility across every stage of fulfillment. Locus delivers this through an AI-powered orchestration layer that addresses core challenges head-on.

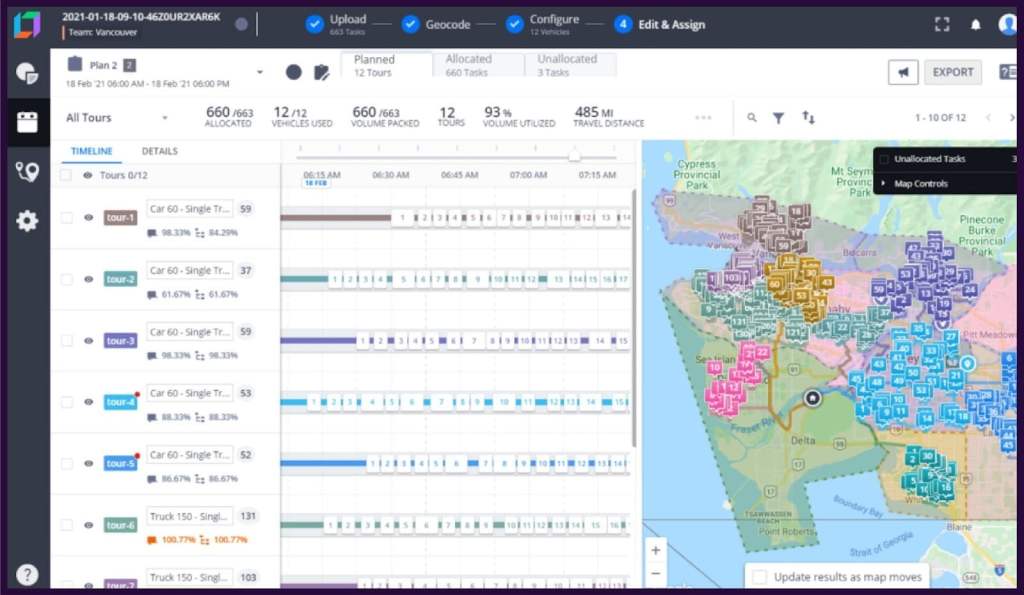

DispatchIQ for Route Optimization

One of the most challenging problems retailers face is rising transportation costs, paired with unpredictable demand. Traditional static routes leave fleets underutilized and customers frustrated by late or missed deliveries.

DispatchIQ addresses this challenge with dynamic route optimization, which balances fleet capacity, service windows, and traffic conditions to maximize route efficiency while reducing costs.

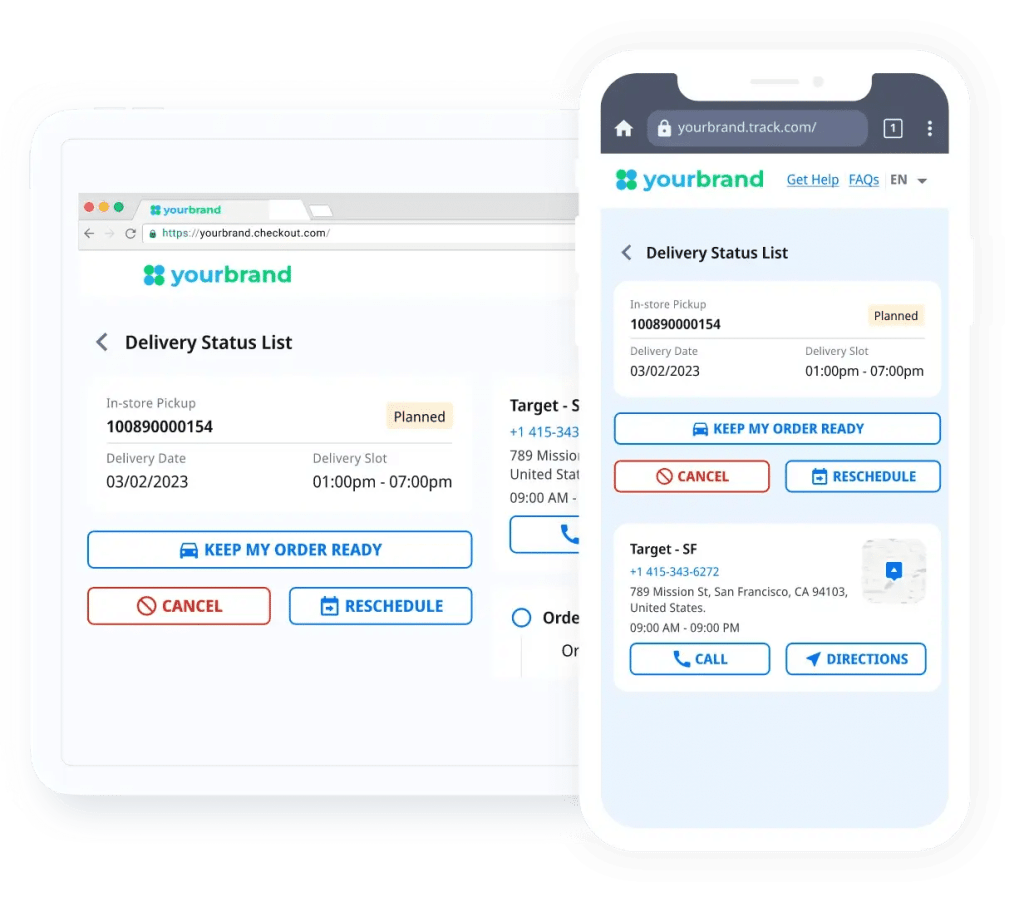

Track & Trace for Visibility

Retailers often struggle with fragmented systems that obscure the location of products, their expected arrival dates, and potential issues that can be prevented.

The Track & Trace software provides a centralized view of shipments, exceptions, and delivery progress, enabling operations teams to make informed decisions and maintain service reliability.

Carrier Management Platform for Delivery Partners

Most retailers rely on multiple third-party carriers, which can result in inconsistent service levels and complex coordination. The Locus Carrier Management Platform streamlines this process by standardizing performance tracking, integrating delivery partners, and enabling retailers to select the optimal carrier for each order. This drives cost savings and consistent customer experiences at scale.

Future-Proof Your Retail Supply Chain With Locus

Retail supply chain management defines how well businesses meet customer expectations while staying profitable. In 2025, retailers that thrive will be those who build agility into their procurement, inventory, warehousing, transportation, and returns processes, while adapting to constant market shifts. The challenge is no longer just about moving goods quickly, but building a system that consistently delivers reliability, efficiency, and customer trust.

Locus combines advanced dispatching, visibility, and partner coordination into a single platform. By transforming complex logistics into simple, data-driven decisions, Locus allows enterprises to cut costs, improve delivery accuracy, and scale confidently across markets.

Ready to see the difference? Schedule a demo and explore how Locus can simplify your retail supply chain management.

Frequently Asked Questions (FAQs)

1. What are common risks in retail supply chain management?

Supply chains face risks like demand fluctuations, supplier disruptions, cyberattacks, and transportation delays. Addressing these requires resilience strategies, strong visibility, and flexible sourcing models.

2. How does technology improve retail supply chain efficiency?

Automation, predictive analytics, and integrated planning tools reduce costs, shorten delivery times, and improve inventory accuracy by connecting all stages of the retail supply chain.

3. What role does sustainability play in retail supply chains?

Sustainability reduces emissions, lowers waste, and supports consumer trust. Practices like reverse logistics and optimized route planning help retailers meet both environmental goals and cost targets.

4. Can retail supply chain management scale across global markets?

Yes, scalable supply chain systems allow retailers to manage cross-border sourcing, complex regulations, and multiple carriers while maintaining consistent service levels.

5. How can retailers simplify complex logistics networks?

Retailers can centralize routing, carrier management, and visibility using advanced platforms. Locus offers an AI-powered orchestration system that helps enterprises cut costs and increase predictability in large-scale retail networks.

![Cloud-based Dispatch Software: A Complete Guide [2025]](https://cdn.sanity.io/images/w495w6xa/production/510cdd269c36b7d8d212790827ba380d1d8c1550-1200x675.webp?fm=webp&q=90)