What is Dispatch Management? Key Components, Best Practices, Challenges

Team Locus

In this article

Key Takeaways

- Dispatch management integrates order validation, driver assignment, routing, monitoring, and analytics into one coordinated workflow.

- Last-mile costs remain the most expensive part of logistics, making efficient dispatch critical for profitability and customer satisfaction.

- Enterprises gain measurable benefits such as lower operating costs, improved driver productivity, and scalability during seasonal peaks.

- Common challenges include rising expenses, labor shortages, fragmented visibility, and compliance pressures.

- Locus streamlines dispatch with AI-powered automation, real-time fleet control, and data-driven insights, enabling enterprises to scale reliably and deliver consistently.

Late or failed deliveries directly undermine customer trust, and logistics leaders feel the impact in revenue. 75% of customers reported experiencing delivery problems in the past year, with many switching providers as a result. Picture a dispatcher managing dozens of orders manually: two high-priority shipments are scheduled for the same driver in overlapping time slots, while another driver waits without assignments. The outcome is predictable, missed commitments, rising costs, and unhappy customers. At the core lies the absence of a structured dispatch management system.

Dispatch management refers to the coordinated process of assigning, scheduling, and monitoring deliveries to match the right resources with the right jobs at the right time.

In this article, you will learn:

- What dispatch management means in 2025

- Why its absence leads to inefficiency and churn

- Core components of an effective system

- Best practices and challenges to address

- How Locus powers smarter dispatch at scale

What Is Dispatch Management?

Dispatch management is the organized process of assigning, scheduling, and tracking deliveries so that every order reaches its destination on time and at the lowest operational cost. It sits at the heart of logistics execution, linking customer demand with the movement of vehicles, drivers, and goods.

In smaller operations, dispatchers often rely on spreadsheets or phone calls to distribute jobs. While workable for a handful of daily orders, such methods quickly collapse under enterprise-scale demand where hundreds of drivers and thousands of shipments must be coordinated in real time. Errors in allocation, underutilized vehicles, and missed delivery windows become frequent consequences.

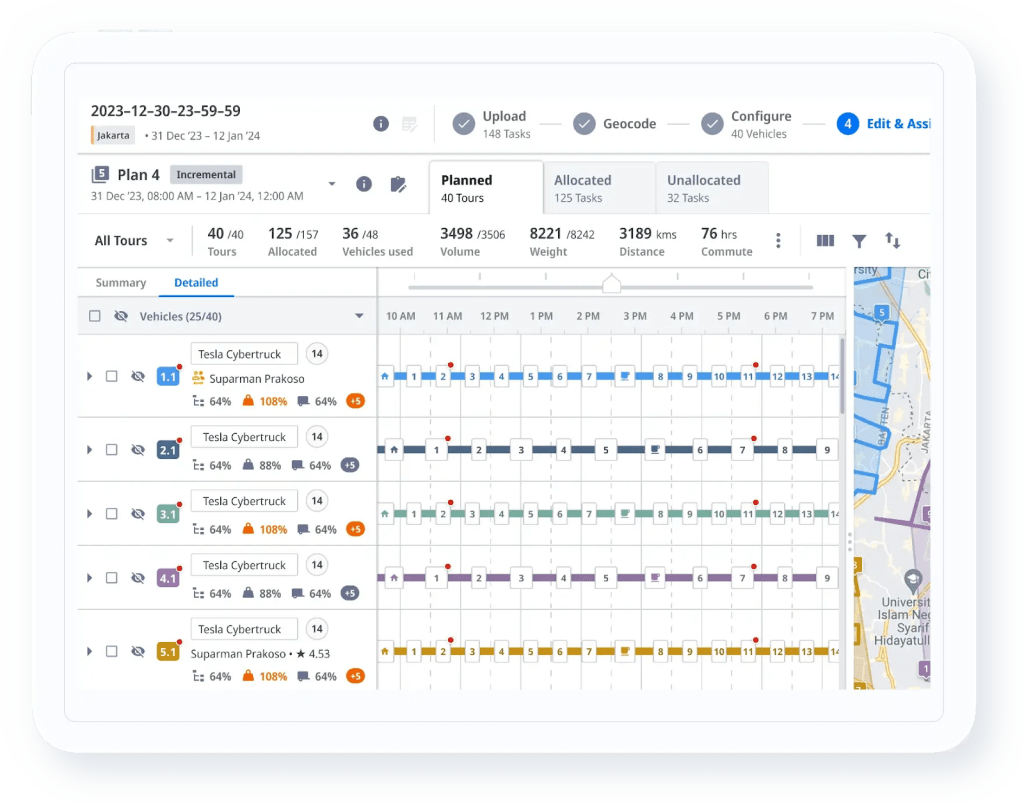

Technology has reshaped the discipline. Modern dispatch platforms consolidate data on orders, fleet capacity, driver schedules, and traffic conditions into a single dashboard. AI-driven systems then evaluate these variables, automatically assigning the most suitable driver, adjusting routes in response to disruptions, and feeding live status updates back to dispatchers.

Two distinct models dominate today’s landscape:

- Manual dispatching: Dependent on individual judgment, prone to delays and uneven workloads.

- Automated, AI-enabled dispatching: Uses algorithms to optimize fleet productivity, reduce miles traveled, and standardize service levels.

Consider an e-commerce company promising same-day delivery across a metro area. Automated dispatching enables balanced driver workloads, shorter delivery windows, and measurable fuel savings. A manual system in the same environment would likely result in late deliveries, higher costs, and dissatisfied customers.

Dispatch management defines whether enterprises achieve reliable fulfillment or struggle with inefficiency and churn.

Suggested read: Locus for Retail: Seamless On-ground Visibility for Dispatch Managers

Why Is Dispatch Management Important?

Last-mile delivery significantly strains operational budgets. An MIT Sloan Management Review study found that delivery on the final leg can account for up to 53% of total supply chain costs, driven by failed deliveries, fuel use, vehicle wear, and rising labor expenses.

The financial impact extends well beyond fuel waste. In urban settings, drivers spend an average of nine minutes searching for parking and walk nearly 8 km per shift, time-intensive, non-productive activities that erode margins. When manual dispatch systems rely on reactive assignments rather than optimization, teams struggle to adjust to shifts in volume or traffic, triggering delays, idle drivers, and missed delivery windows.

In contrast, AI-based dispatch management enables dynamic driver assignment, adaptive routing, and proactive monitoring. An example: a grocery delivery operator maintaining tight two-hour delivery windows while cutting fuel consumption through algorithmic route optimization.

Today, effective dispatch management is a strategic asset. It shapes cost structure, delivery dependability, and customer trust, and without it, enterprises risk losing both profit and performance.

Different Components of Dispatch Management

Dispatch management is not a single task but a series of interconnected functions that ensure every delivery moves seamlessly from assignment to completion. Each component addresses a different part of the workflow:

1. Order Capture and Validation

The process begins with incoming orders. Dispatch systems verify addresses, promised delivery windows, and service-level requirements before assigning jobs. Accurate validation prevents errors such as duplicate entries or incorrect routing.

2. Fleet and Driver Assignment

Driver schedules, vehicle capacity, and skill sets (e.g., handling perishables or oversized items) determine who receives which delivery. Automated systems can weigh these variables in seconds, while manual allocation often introduces mismatches and delays.

3. Route Planning and Optimization

Once drivers are assigned, algorithms calculate the most efficient sequence of stops, considering traffic patterns, delivery time commitments, and fuel consumption. Optimization reduces empty miles and balances workloads.

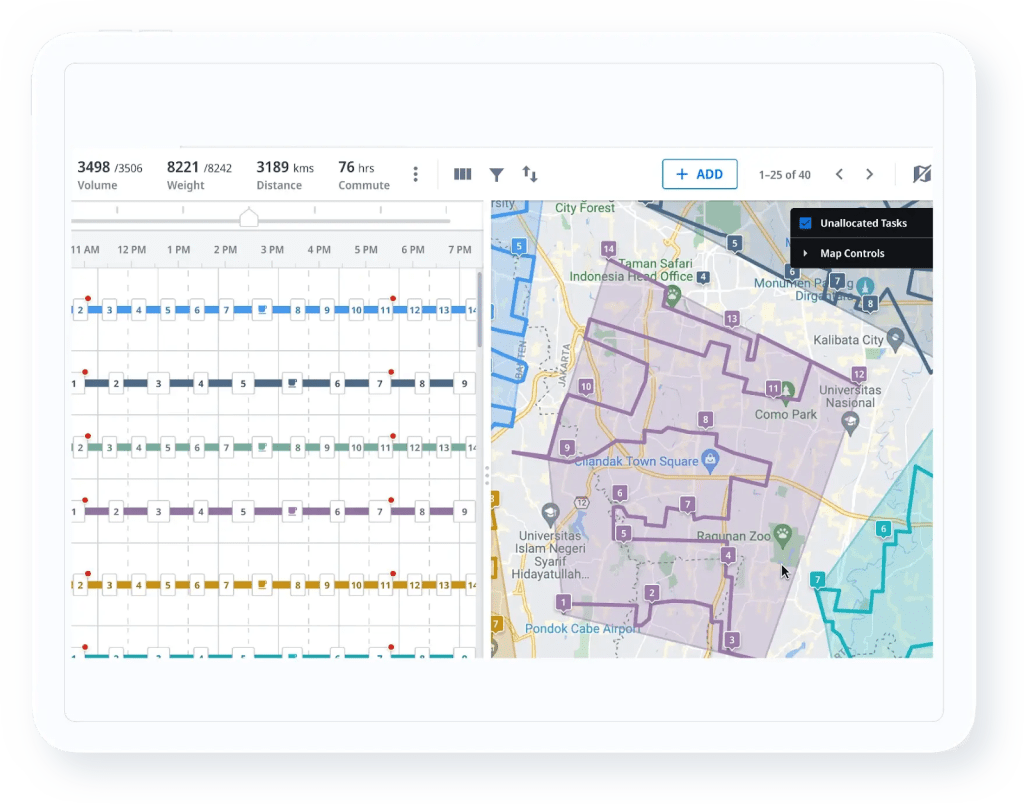

4. Real-Time Tracking and Monitoring

GPS-enabled platforms track every vehicle in motion. Dispatchers gain live visibility into driver locations, route adherence, and estimated arrival times, allowing them to intervene if issues arise.

5. Exception Handling and Resolution

Unexpected disruptions, ranging from traffic accidents to customer no-shows, demand quick responses. Advanced dispatch systems automatically reroute drivers, reschedule deliveries, or divert orders to pickup hubs to minimize impact.

6. Customer Communication

Customers expect timely updates. Automated notifications, mobile tracking links, and accurate ETAs reduce inbound calls to support teams and improve satisfaction.

7. Analytics and Reporting

Post-delivery analysis highlights performance trends such as on-time delivery rates, fuel use, and driver productivity. These insights feed continuous improvement initiatives.

For example, a 3PL managing a nationwide retail client may use dispatch software to integrate all these components into a single dashboard. Instead of relying on separate systems for assignment, routing, and tracking, dispatchers oversee operations holistically, cutting coordination time and increasing reliability.

When these components function in sync, enterprises can deliver faster, reduce costs, and adapt to volatile demand with confidence.

Suggested read: What is Route Optimization?

What are the Benefits of Implementing Dispatch Management?

Enterprises adopting structured dispatch management unlock advantages that extend across cost, efficiency, and customer experience. Modern systems driven by automation and AI provide measurable gains:

1. Lower Operating Costs

Optimized driver assignments and fuel-efficient routes directly reduce mileage and fuel consumption. For fleets covering large urban territories, even a 5% reduction in fuel spend can translate to millions saved annually.

2. Higher Customer Satisfaction

Reliable, on-time deliveries strengthen customer loyalty. Automated notifications and accurate ETAs improve transparency, giving customers confidence that their orders will arrive when promised.

3. Improved Driver Productivity

Balanced workloads prevent overburdening some drivers while others remain idle. Intelligent dispatching ensures drivers spend more time on the road completing deliveries and less time waiting for assignments.

4. Scalability During Demand Peaks

Seasonal surges, flash sales, and promotional events often overwhelm manual dispatch systems. Automated platforms flex capacity quickly, reallocating deliveries across available resources without additional headcount.

5. Better Resource Utilization

Dispatch tools maximize vehicle capacity by considering load size, weight limits, and delivery sequence. This reduces the number of underutilized trips and improves overall fleet efficiency.

6. Compliance and Safety Assurance

Modern platforms can factor in driver hours-of-service regulations, vehicle restrictions, and local delivery rules. This reduces compliance risks and keeps drivers operating within safe limits.

7. Continuous Improvement Through Data

Analytics highlight metrics such as on-time rates, delivery costs per mile, and exceptions resolved. These insights support better decision-making and long-term optimization strategies.

For instance, a consumer electronics retailer implementing automated dispatch saw shorter delivery windows and a measurable drop in late deliveries, strengthening both cost control and customer retention.

In practice, enterprises that integrate dispatch management gain more than operational efficiency: they build scalable, resilient delivery networks that adapt to changing customer expectations.

Locus enhances these benefits with its AI-powered dispatch solutions. DispatchIQ automates order-to-driver assignments for maximum fleet productivity, while the Control Tower gives dispatchers real-time visibility to resolve exceptions proactively. By integrating optimization, monitoring, and customer communication into one platform, Locus enables enterprises to cut operating costs, meet strict delivery windows, and scale seamlessly during peak demand.

Best Practices in Dispatch Management

Enterprises managing high delivery volumes cannot rely on ad-hoc methods. To keep operations cost-efficient and reliable, dispatch management must follow structured best practices that align people, processes, and technology.

1. Automate Repetitive Tasks

Manual allocation consumes valuable time and often leads to bottlenecks. Automated dispatch platforms evaluate orders, driver availability, and traffic conditions instantly, ensuring resources are used efficiently without overburdening dispatch teams.

2. Maintain Real-Time Visibility

Centralized dashboards give dispatchers live insight into driver locations, vehicle status, and delivery progress. Proactive monitoring enables faster responses when delays or exceptions occur, keeping service levels intact.

3. Use Predictive Analytics

Historical data on demand surges, traffic congestion, or delivery failures can be applied to forecast future challenges. Predictive analytics equips dispatchers to reroute drivers before problems escalate, reducing last-minute disruptions.

4. Integrate with Upstream and Downstream Systems

Dispatch management becomes more effective when connected to order management, inventory, and customer engagement systems. Integration eliminates silos, reduces duplicate entries, and ensures the same information is available across functions.

5. Empower Dispatch Teams

Technology is only part of the equation. Training dispatchers to interpret system insights, prioritize exceptions, and manage escalations builds resilience in day-to-day operations.

6. Optimize for the Customer Experience

Providing accurate ETAs, automated notifications, and transparent tracking links helps customers stay informed and reduces the volume of “where is my order” calls.

For example, a logistics provider using automated dispatch optimization software avoided 12% in wasted miles during a peak season by combining predictive routing with proactive communication. Practices like these transform dispatching from a reactive task into a strategic function that drives both efficiency and loyalty.

To put these principles into action, logistics teams can use the following checklist to evaluate and refine their dispatch operations:

Best Practices in Dispatch Management – Checklist

- Automate order-to-driver assignments to minimize allocation delays

- Track fleets in real time with centralized dashboards

- Use predictive analytics to forecast and prevent disruptions

- Connect dispatch with order, inventory, and customer engagement systems

- Train dispatchers to interpret insights and resolve exceptions quickly

- Share accurate ETAs and live tracking links with customers

While these practices build a strong foundation for efficient operations, enterprises still face structural and operational hurdles that complicate dispatch management.

Challenges in Dispatch Management

Even with digital tools, enterprises encounter persistent challenges that disrupt fleet performance and increase costs. These issues typically fall into five areas:

1. Rising Operational Costs

Fuel prices, driver wages, and vehicle maintenance expenses continue to climb. Without continuous optimization, these costs quickly erode delivery margins.

2. Demand Fluctuations

Seasonal spikes, promotional campaigns, and sudden demand shifts strain dispatch systems. Manual processes often fail to reallocate resources fast enough, leading to bottlenecks and missed deliveries.

3. Driver Availability and Retention

Labor shortages remain a global concern. High turnover among drivers forces enterprises to constantly train new staff, while inexperienced teams increase the risk of errors and delays.

4. Limited Visibility Across Networks

In fragmented supply chains with multiple carriers and regions, dispatchers struggle to maintain end-to-end visibility. Lack of transparency makes it difficult to monitor performance or resolve exceptions promptly.

5. Regulatory and Compliance Pressures

Enterprises must comply with rules covering vehicle restrictions, driver working hours, and regional delivery standards. Overlooking these factors exposes companies to fines and reputational damage.

For example, during a holiday surge, an e-commerce player relying on spreadsheets may overload certain drivers, breach delivery promises, and face compliance risks due to missed rest-hour checks. These recurring challenges highlight the need for integrated, AI-powered systems that anticipate problems rather than react to them.

Case Study: FMCG Enterprise Overcomes Dispatch Bottlenecks

Locus helps FMCG enterprises cut delivery costs, reduce empty miles, and boost fleet visibility with AI-powered dispatch automation.

A leading FMCG company operating across multiple regions faced mounting dispatch challenges. Manual planning left fleets underutilized, rising fuel and labor costs eroded margins, and lack of real-time visibility made it difficult to monitor delivery performance. During peak seasons, these issues compounded, resulting in missed deadlines and dissatisfied retail partners.

Read the entire case study here!

By adopting Locus’ Transportation Management System (TMS), the company replaced fragmented processes with automated dispatch planning and centralized fleet visibility. The platform optimized vehicle allocation, reduced empty miles, and gave dispatchers real-time insights into delivery progress. As a result, the enterprise achieved faster order fulfillment, lower operational costs, and improved reliability across its nationwide supply chain.

Schedule a demo

How Locus Streamlines Dispatch Management in 2025

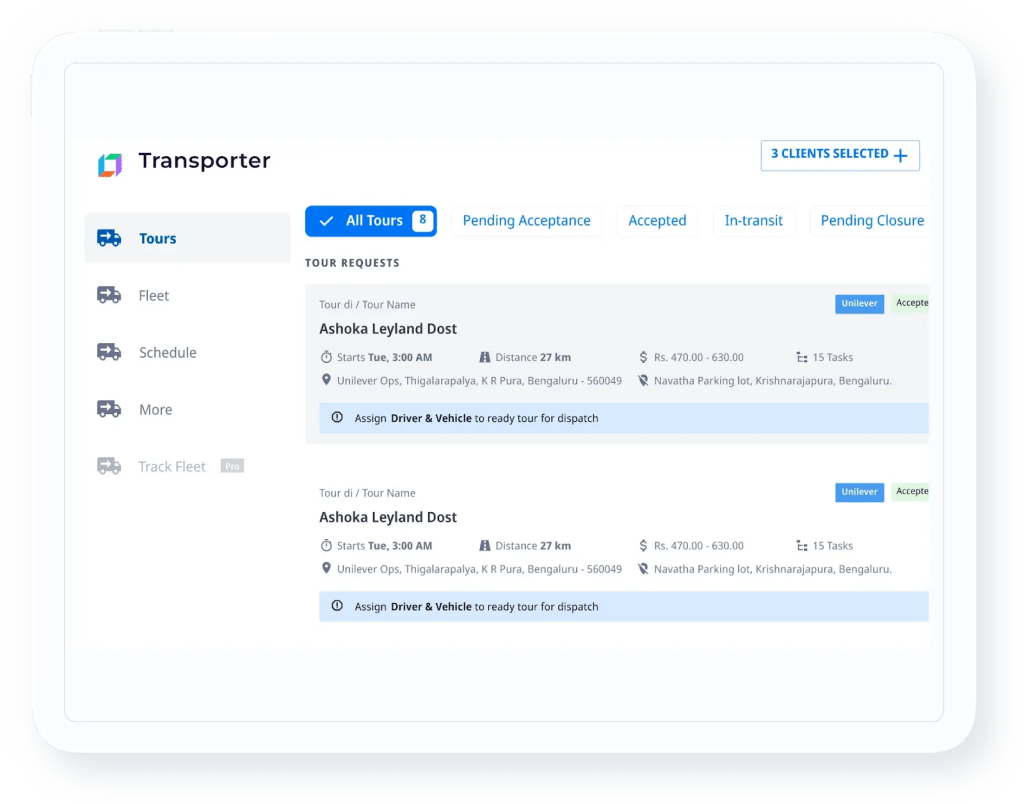

Locus redefines dispatch management by combining automation, predictive intelligence, and real-time control into a single platform. Instead of treating dispatching as a stand-alone function, the system connects assignment, monitoring, and optimization so enterprises can operate at scale with precision.

Automated Dispatch with DispatchIQ

DispatchIQ analyzes order details, delivery windows, traffic conditions, and driver availability simultaneously to allocate jobs in seconds. Fleets avoid idle time, workloads remain balanced, and vehicle capacity is consistently maximized.

Real-Time Visibility with Control Tower

The Control Tower tracks every driver and vehicle in motion, displaying live status updates and route adherence. Dispatchers gain the ability to detect delays early and take corrective action, rerouting drivers or rescheduling deliveries before service levels are compromised.

Order-to-Delivery Workflow Automation

Failed deliveries increase costs by as much as 15%. Locus mitigates this with automated workflows for rescheduling, rerouting, and customer notifications. Customers receive accurate updates, while enterprises preserve profitability through reduced exceptions.

Carrier Management Optimization

For businesses managing multiple third-party carriers, Locus evaluates cost, capacity, and service history to recommend the most effective partner for each delivery. This data-driven approach ensures both lower costs and dependable execution.

Actionable Analytics

Performance dashboards surface critical metrics such as cost per mile, on-time delivery rates, and exception frequency. Leaders use these insights to refine fleet strategy, model new service levels, and scale into new regions with confidence.

By unifying automation and intelligence, Locus elevates dispatch management from a tactical necessity to a strategic enabler of growth.

Book a demo with Locus and discover how AI-driven dispatch management accelerates growth and efficiency across delivery networks.

Frequently Asked Questions (FAQs)

1. How does dispatch management differ from route planning?

Route planning focuses on sequencing stops efficiently, while dispatch management covers the entire process, order validation, driver assignment, live monitoring, exception handling, and reporting. It ensures deliveries are executed reliably, not just routed efficiently.

2. What industries benefit most from dispatch management systems?

Retail, e-commerce, FMCG, 3PLs, and CEP providers see the strongest benefits. These industries handle large order volumes, tight delivery windows, and frequent demand fluctuations, making dispatch optimization critical for cost control and service reliability.

3. How can dispatch management help during seasonal peaks?

AI-powered dispatch platforms dynamically reassign deliveries, balance workloads across drivers, and reroute in real time. This flexibility allows enterprises to absorb sudden spikes in orders without adding excess vehicles or headcount.

4. What KPIs should enterprises track to measure dispatch performance?

Key metrics include on-time delivery rate, cost per mile, vehicle utilization, failed delivery percentage, and exception resolution time. Tracking these KPIs helps enterprises assess efficiency and identify improvement areas.

5. How does Locus improve dispatcher productivity?

Locus automates manual tasks such as driver assignment and exception handling, while providing live dashboards for decision-making. Dispatchers spend less time on repetitive coordination and more time focusing on high-priority issues, leading to smoother and more scalable operations.

![Cloud-based Dispatch Software: A Complete Guide [2025]](https://cdn.sanity.io/images/w495w6xa/production/510cdd269c36b7d8d212790827ba380d1d8c1550-1200x675.webp?fm=webp&q=90)